- Home

- Bray

- Ball Valves

- Series 19/19L

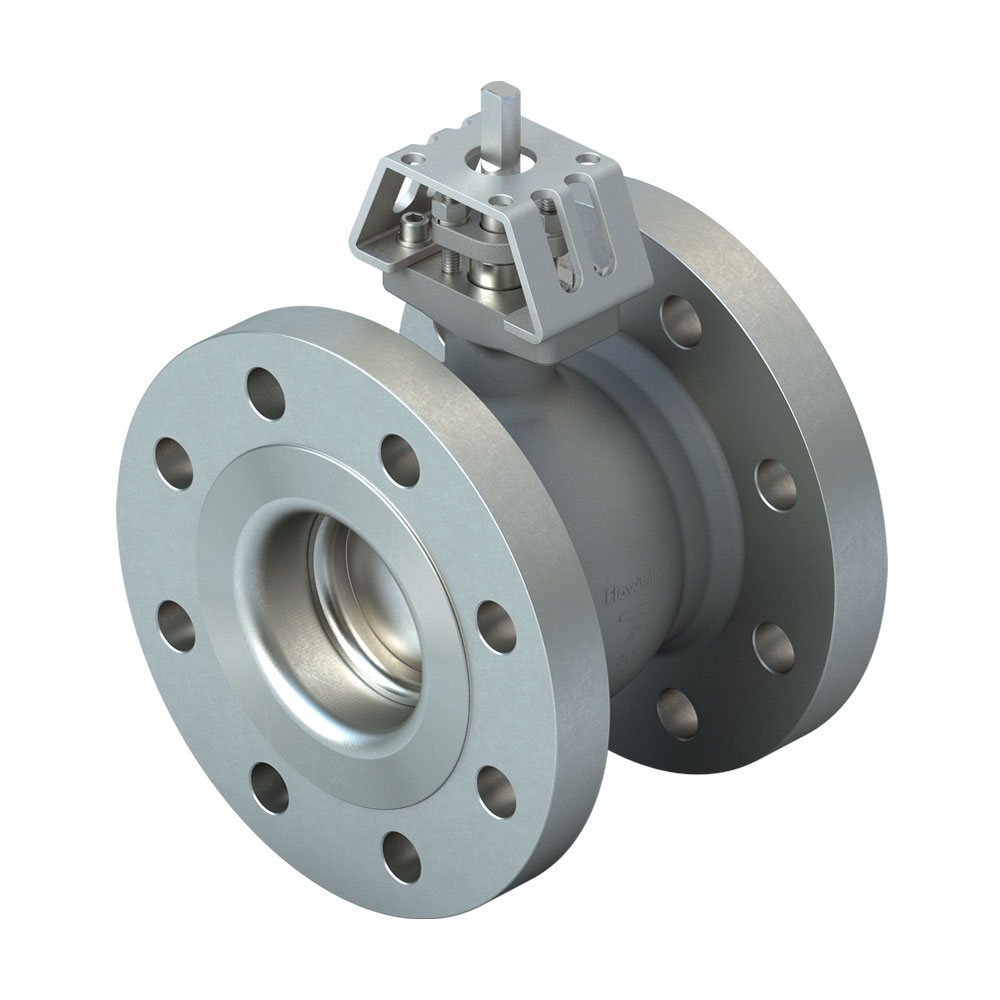

Series 19/19L

Segmented Ball Valve

Specifications

| Size Range | NPS 1 to 16 / DN 25 to 400 |

|---|---|

| Temperature Range | -50°F to +500°F (-46°C to +260°C) |

| Maximum Allowable Operating Pressure | ASME Class 150, 300, 600 |

| Shutoff Rating | Metal Seat: Class IV per IEC 60534-4 /ANSI/ FCI 70-2, |

| Body Style | One Piece |

| End Connections | Flanged, Flangeless (Wafer) |

| Body Materials | Stainless Steel (CF8M), Carbon Steel (WCB), 316L |

| Stem Materials | 17-4PH, Nitronic 50 (XM-19), Super Duplex, SMO 254 Stainless Steel |

| Seat Materials | Resilient Seat: (316) Stainless Steel w/ Tek-Fil® Insert (S19) |

| Ball Materials | S19: Stainless Steel (CF8M), CF8M Hard Chrome Plated |

| Design Standard | ASME B16.34 |

| Ports | Reduced Port: 90° (Standard), 60°, 30°, and customized segment characterization profiles available |

| Applications | On/Off and Control Applications in: Pulp and Paper, Sugar and Ethanol Production, Mining, Oil and Gas, Power, Refining, Chemical, Food and Beverage, HVAC, and other highly abrasive slurry applications. |

| Certifications | CRN, ISO 15848, PED, PED(S)R, TR CU, TSG, UA.TR.089 |

Features & Benefits

The Series S19/S19L segmented ball valves are designed for modulating control and on-off services in gas, liquid and slurry applications.

These segmented ball valves deliver exceptional performance with the precision, features and options for superior control in a wide variety of industries and applications.

The Series S19 combines the shearing action of a knife gate valve, control characteristics of a globe valve and sealing performance of a ball valve. It features a characterized segment for high rangeability and high flow capacity in an economical product that delivers exceptional control valve performance.

The Series S19L combines the versatile design of the standard S19 with advanced trims for highly abrasive slurry and severe applications that often lead to erosion in traditional valves. Bray’s proprietary advanced coating technology is applied to the internal components of the valve to provide increased hardness and bond strength over other commonly used coating technologies